Company

What kind of company takes 60 years of accepted standards and throws them away?

Founded in 1966

DeltaHawk was founded in 1996 by Doug & Diane Doers and John (JP) Brooks. Doug was an experienced military and civilian pilot and mechanical engineer, Diane had extensive business experience, and JP was an experienced military pilot and American Airlines Captain. Together, they had the vison to create a modern engine that was cleaner, more efficient, and required less maintenance along with bringing improved performance and higher reliability to General Aviation.

This highly ambitious project turned out to be substantially more difficult and much more costly than they imagined, but their stubborn perseverance drove them to continue towards their goal, long after most others would have given up. Through many years of dedicated effort, averaging only 2-3 employees, progress was slow, with lack of funding being the major impediment to both engine completion and achieving FAA Type Certification. In 2015, Al and Chris Ruud became aware of DeltaHawk’s situation, so with their shared vision, dedication, perseverance and financial support the engine achieved FAA Type Certification in 2023.

Factory

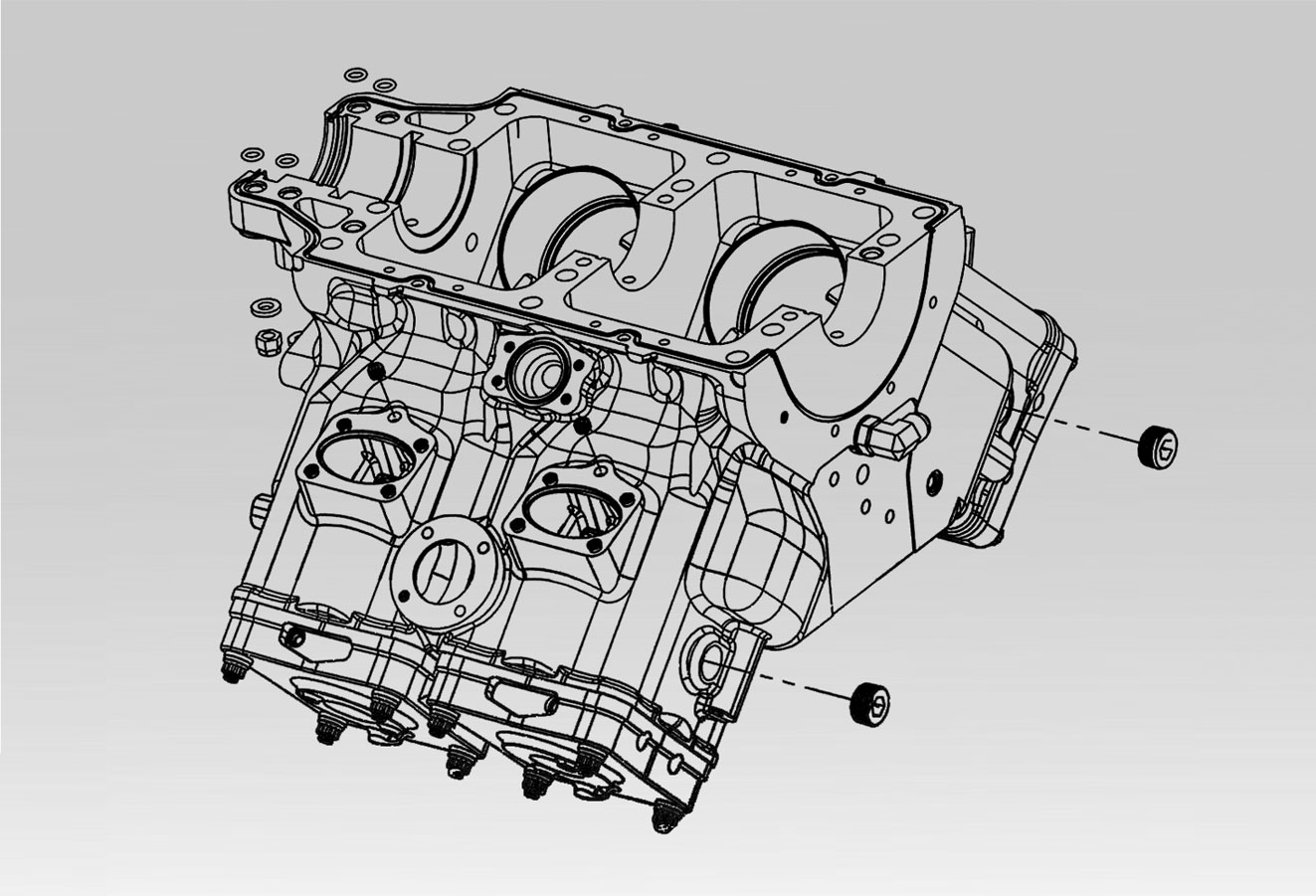

Our campus, adjacent to Batten International Airport (KRAC) in Racine, Wisconsin, centralizes more than 85,000 square feet of facilities. Thanks to significant investment, we are able to design, assemble and test virtually every critical component of our engines in-house, allowing precise quality control throughout the build process. We operate state-of-the art facilities for engine and subsystems testing—including fuel and cooling systems, superchargers and propellers, along with ISO Class 8 clean rooms, installation kit development teams, fabrication and assembly capabilities, and flight test.

Company Timeline

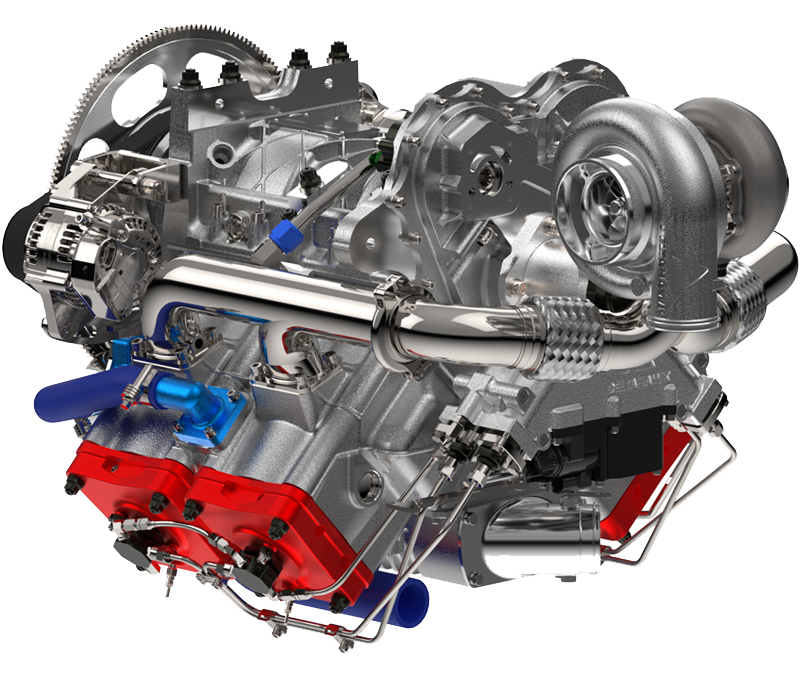

DeltaHawk Aerospace Company has Revolutionized the Plane Engine

1996

Company formed to develop clean sheet compression engine with unique, pilot-inspired, technology and features.

1998

Prototype engine running on static Velocity RG airframe.

2011

State of Wisconsin provides low-interest funding for manufacturing facilities. DeltaHawk moved to its current facilities.

2014

DeltaHawk engine installed in a Cirrus SR20 is flown from Florida to Oshkosh and shown at EAA AirVenture.

2015

Majority investment and guidance from Chris and Al Ruud, experienced commercialization entrepreneurs.

2017

Ramped-up testing begins.

2018

FAA certification testing begins on the DHK-series engine.

2019

DeltaHawk Engines grows from the original three employees to 60.

2020

Final FAA certification testing and readiness activities include design, performance and technical process upgrades, and additional endurance testing.

2023

Final FAA certification achieved! Design, performance and technical upgrades are underway along with more endurance testing. Production ramp-up is in full-swing, and we expect first engine deliveries to commence in 2026.